Tupu ọgwụgwọ ntuziaka mfe usoro na akpaka tupu usoro ọgwụgwọ, nke ikpeazụ na-ekewa n'ime akpaka ịgba na akpaka itinye ịgba abụọ usoro.The workpiece ga-n'elu mesoo iji wepụ mmanụ na nchara tupu spraying.N'akụkụ a, a na-eji mmiri mmiri ndị ọzọ eme ihe, tumadi onye na-ewepụ nchara, onye na-eme ihe na-emebi emebi, nhazi tebụl, onye ọrụ phosphating na ihe ndị ọzọ.

Na ngalaba nhazi ma ọ bụ ogbako tupu akara mmepụta ihe osise, a ga-akwụ ụgwọ nlebara anya na nguzobe nke ịzụrụ ihe dị mkpa, njem, nchekwa na iji acid siri ike na usoro alkali, iji nye ndị ọrụ uwe nchebe dị mkpa, uwe mkpuchi dị mma na nke a pụrụ ịdabere na ya. njikwa, nhazi nke ngwa ngwa, yana mmepe nke usoro ọgwụgwọ mberede na usoro nnapụta ma ọ bụrụ na ihe mberede.Nke abuo, na pretreatment ngalaba nke eserese mmepụta akara, n'ihi na ịdị adị nke a ụfọdụ ego nke mkpofu gas, mmiri mmiri na-ekpofu ihe na ihe atọ ndị ọzọ na-emebi ihe, ya mere, n'ihe banyere nchebe gburugburu ebe obibi, ọ dị mkpa ịhazi iyuzucha ikuku, mkpofu mmiri na mmiri. ngwaọrụ ọgwụgwọ mkpofu atọ.

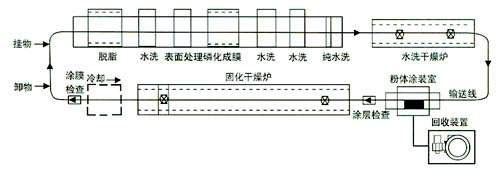

The àgwà nke tupu emeso workpiece kwesịrị dị iche iche n'ihi na dị iche iche pretreatment ngwọta na mkpuchi mmepụta akara usoro.Mma nhazi nke workpiece, n'elu mmanụ, nchara ime, iji gbochie a obere oge nke oge nchara ọzọ, n'ozuzu kwesịrị ịbụ na pretreatment mgbe ọtụtụ usoro, phosphating ma ọ bụ passivation ọgwụgwọ: tupu spraying ntụ ntụ, nwekwara kwesịrị inwe phosphating workpiece. maka ihicha, ka elu mmiri ya.Obere ogbe otu mmepụta, na-ejikarị ihicha ikuku eke, ihicha anwụ, ihicha ikuku.Na maka nnukwu ọrụ eruba, na-ewekarị ihicha okpomọkụ dị ala, na-eji oven ma ọ bụ okporo ụzọ ihicha.

Ịgbasa ntụ ntụ mkpuchi nzukọ mmepụta

Maka obere ogbe workpiece, a na-anakwere ngwaọrụ ntụ ntụ n'aka, yana maka nnukwu batch workpiece, akwụkwọ ntuziaka ma ọ bụ akpaaka na-ejikarị eme ihe.Ma akwụkwọ ntuziaka ma ọ bụ uzuzu akpaaka, njikwa mma dị ezigbo mkpa.Iji hụ na spraying workpiece ntụ ntụ edo, na-agbanwe agbanwe ọkpụrụkpụ, iji gbochie mkpa ịgba, ntapu ịgba, hichapụ na ndị ọzọ ntụpọ.

mkpuchi mkpuchi mmepụta akara na usoro, ma kwesịrị ịṅa ntị na nko akụkụ nke workpiece, tupu abanye na-agwọ ọrịa, kwesịrị rube isi na ya ntụ ntụ dị ka o kwere omume ga-ịfụ pụta, gbochie ngafe ntụ ntụ ọgwụgwọ nke nko, ụfọdụ maka ọgwụgwọ wepụ ihe fọdụrụ ntụ ntụ. tupu ihe isi ike, kwesịrị n'oge ịdọpụ nko nwere solidified ntụ ntụ film, conductive iji hụ na nko dị mma, na ọnụ ọgụgụ nke artifacts na ntụ ntụ.

Njikwa mmepụta nke usoro ọgwụgwọ na ahịrị mkpuchi

Usoro a kwesịrị ntị ka: sprayed workpiece, ma ọ bụrụ na ọ bụ a obere ogbe nke otu mmepụta, n'ime na-agwọ ọkụ tupu ịṅa ntị iji gbochie ịda ntụ ntụ, dị ka ntụ ntụ rubbing onu, kwesịrị n'oge ịgba ntụ ntụ.Mgbe ị na-esi nri, usoro siri ike na okpomọkụ, njikwa oge, ṅaa ntị iji gbochie ọdịiche agba, n'elu achịcha ma ọ bụ oge dị mkpirikpi nke n'ihi enweghị ọgwụgwọ zuru oke.

N'ihi na nnukwu quantities nke akpaka nnyefe nke workpiece, na ihicha ụzọ tupu nwekwara nlezianya lelee ma leakage ịgba, ịgba mkpa ma ọ bụ mpaghara ntụ ntụ onu, dị ka hụrụ na-erughị eru akụkụ, ga-emechi iji gbochie ịbanye ihicha ụzọ, dị ka o kwere mee ka gbadaa ihe nfe.Ọ bụrụ na onye workpiece adịghị eru eru n'ihi mkpa ịgba, ọ nwere ike re-sprayed na solidified ọzọ mgbe ọgwụgwọ.

Oge nzipu: Jan-17-2022