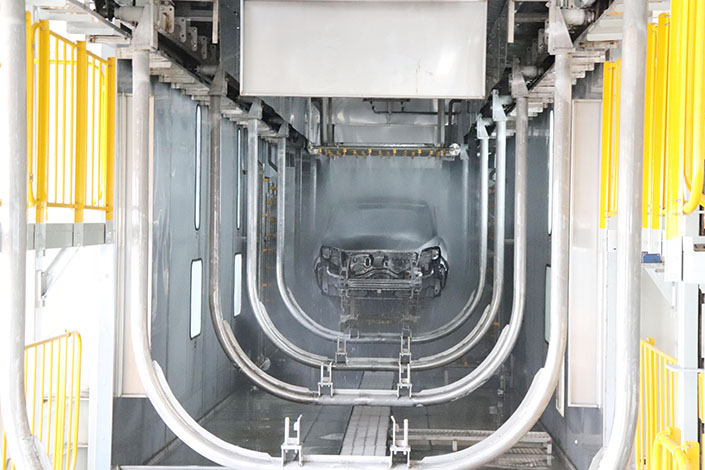

Ịgba ụdị pretreatment mmepụta ahịrị

Mkpuchi pretreatment na-agụnye degreasing (degreasing), mwepụ nchara, phosphating akụkụ atọ.Phosphating bụ njikọ dị n'etiti, nkwụsị na iwepụ nchara bụ usoro nkwadebe tupu phosphating, ya mere na mmepụta mmepụta, ọ bụghị nanị na anyị ga-ewere ọrụ phosphating dị ka ihe a na-elekwasị anya, kamakwa malite na ihe ndị a chọrọ nke àgwà phosphating, rụọ ọrụ dị mma na mgbakwunye. mmanụ na mkpochapụ nchara, karịsịa ṅaa ntị na mmetụta dị n'etiti ha.

Na-eweda ya iwe

Site na mmepe nke ụlọ ọrụ, nchebe gburugburu ebe obibi na mmelite nke ọnọdụ ọrụ aghọwo ihe na-emekarị ndị mmadụ.Ya mere, mkpa nke nchekwa gburugburu ebe obibi kwesịrị iburu n'uche mgbe ị na-ahọrọ ndị ọrụ.Ya mere, nhọrọ nke onye na-ewepụ mmanụ na-achọ nkwadebe dị mfe, ike nkwụsị dị ike, enweghị sodium hydroxide, silicate, OP emulsifier na ihe ndị ọzọ siri ike dị ọcha na ụlọ okpomọkụ, dị mfe ịsacha na ụlọ okpomọkụ, ọ dịghị ihe na-egbu egbu. ihe, adịghị emepụta gas na-emerụ ahụ, ọnọdụ ọrụ dị mma.Nhọrọ nke nchara remover chọrọ nsonye nke nkwalite, corrosion inhibitors na inhibitors, nwere ike melite ọsọ nke nchara mwepụ, gbochie workpiece si n'elu-corrosion na hydrogen embrittlement, nwere ike mma inhibit acid fog.Kwesịrị ekwesị karịsịa acid alụlụ inhibiting, na-eme na usoro pickling acid alụlụ, corrosion nke akụrụngwa na osisi, ọ bụghị nanị na-emetọ gburugburu ebe obibi, na nwere ike ime ka eze ire ere, eze conjunctival ọbara ọbara, anya mmiri, mgbu, akpịrị akpịrị, ụkwara na mgbaàmà ndị ọzọ. , yabụ na-egbochi alụlụ acid nke ọma, ọ bụghị naanị mkpa nchekwa gburugburu ebe obibi, ma ọ bụ maka ahụike maka mkpa onye ọrụ.

Ịsacha mmiri

Ịsacha mgbe mwepụ mmanụ na nchara nchara, ọ bụ ezie na ọ bụ usoro inyeaka tupu eserese, ọ dịkwa mkpa ka ọ kpata nlebara anya zuru oke.Mgbe mmanụ wepụ na nchara mwepụ, n'elu nke workpiece dị mfe rube isi na ụfọdụ ndị na-abụghị ionic surfactants na CL-.Ọ bụrụ na emeghị ka ihe ndị a fọdụrụnụ ihicha nke ọma, ha nwere ike ime ka ihe nkiri phosphating na-ebelata, ntụpọ ahịrị, na ọbụna phosphating.Ya mere, iji melite ogo nke ịsacha mmiri mgbe e wepụsịrị mmanụ na nchara, ọ dị mkpa ịgafe ọtụtụ rinses, rinses abụọ, oge 1-2min, na-eji dochie anya mmiri ugboro ugboro iji hụ na uru PH nke mmiri dị n'etiti 5-7. .

Phosphating

Nke a na-akpọ phosphating, na-ezo aka na metal workpiece mgbe nwere dihydrogen phosphate acid ngwọta ọgwụgwọ, chemical mmeghachi omume na n'elu ya n'ịwa a oyi akwa nke ike insoluble phosphate film, ihe nkiri na-akpọ phosphating film.Ebumnuche bụ isi nke ihe nkiri phosphating bụ iji mee ka adhesion nke mkpuchi dịkwuo elu ma melite nguzogide corrosion nke mkpuchi.E nwere ọtụtụ ụzọ nke phosphating, dị ka okpomọkụ nke phosphating nwere ike kewaa elu okpomọkụ phosphating (90-98 ℃), ọkara okpomọkụ phosphating (60-75 ℃), ala okpomọkụ phosphating (35-55 ℃) na nkịtị okpomọkụ. phosphating.

Mmasị

A na-eji teknụzụ passivation nke ihe nkiri phosphating eme ihe na North America na mba Europe.Teknụzụ passivation dabere na njirimara nke ihe nkiri phosphating n'onwe ya.Ihe nkiri phosphating dị gịrịgịrị, n'ozuzu na 1-4G / m2, nke kachasị abụghị ihe karịrị 10g / m2, oghere oghere n'efu dị ukwuu, na nkwụsị corrosion nke ihe nkiri ahụ n'onwe ya dị oke.Ụfọdụ ọbụna na ihicha usoro na ngwa ngwa odo ajari, mgbe phosphating a passivation mechiri emechi ọgwụgwọ, nwere ike ịbụ phosphating film pore kpughere metal oxidation, ma ọ bụ guzobe passivation oyi akwa, phosphating film nwere ike igwu a ndochi, oxidation, mee phosphating film kwụsie ike na phosphating film kwụsie ike na phosphating. ikuku.

Ihicha ihe nkiri phosphating

Ikpocha ihe nkiri phosphating nwere ike ịrụ ọrụ abụọ, n'otu aka ahụ, ọ bụ iji kwadebe maka usoro ọzọ iji wepụ mmiri dị n'elu ihe nkiri phosphating, n'aka nke ọzọ, ọ bụ iji meziwanye nguzogide corrosion nke ihe nkiri ahụ. mgbe mkpuchi.

Iji guzobe ahịrị pretreatment mkpuchi mkpuchi, a ga-emerịrị usoro nhazi tupu imepụta, nrụpụta na ntinye nke akụrụngwa na-abụghị ọkọlọtọ.Ya mere, nhazi usoro bụ ntọala nke eriri mmepụta, na ụzọ ziri ezi na ezi uche ga-enwe mmetụta dị mma na ọrụ mmepụta na àgwà ngwaahịa.

A na-eji eserese workpiece niile, ụdị ndị ọzọ nwere ike ịhazi ya.